In quality control, the Container Closure Integrity Test (CCIT) identify seal and structural integrity defects in ready-to-market products. CCIT is non-destructive and non-invasive so it can be used to inspect the entire production. It also accurately identifies and rejects all defective items, thereby improving the quality of the final products to be placed in the market.

Regulations are especially stringent in the pharmaceutical industry, in which the main governing bodies are the USP (United States Pharmacopeia), GMP (Good Manufacturing Practices) and Annex 1 of the European Union, with standards like ASTM International (formerly American Society for Testing and Materials).

International standards group tests into two main families: probabilistic tests and deterministic tests. The general rule is to use deterministic tests whenever possible as they provide reproducible results and are non-destructive. This means that the entire production run can be tested, eliminating all products with seal or integrity defects, and limiting waste due to false positives.

Regulations list certain types of deterministic tests:

- High Voltage Leak Detection (HVLD)

- Laser-based Headspace Gas Analysis (HGA)

- Mass Extraction

- Tracer Gas (vacuum mode)

- Vacuum Decay Method (VDM)

- Pressure Decay Method (PDM)

The Vacuum Decay Method (VDM) and the Pressure Decay Method (PDM) are particularly flexible and suitable for in-line use. Both test methods are based on the same physical principles: the flow rate of a fluid through a hole depends on the difference in pressure on both sides of the wall that is passed through. As the fluid flows through the hole, the pressure around the product changes. Based on these principles, if a pressure variation is detected around the product, it is certain that there is a hole in the package. The size of the hole can be determined precisely by measuring the flow rate.

In both types of test, a pressure difference is generated between the inside and the outside of the container via vacuum or pressure, depending on the type of product being tested. The pressure outside the container is measured twice, a few seconds apart. If a pressure variation is found that is higher than the threshold value set during machine configuration, the product is identified as damaged and is rejected.

How does machine calibration affect test sensitivity?

VDM and PDM testing machines identify the presence of a hole by detecting a pressure difference between two measurements taken at different times. The more time that can pass between the readings, the more precise the test will be in determining the size of the hole. This means that longer testing times will allow detection of smaller holes. However, pressure is not linear with respect to flow, so doubling the test time will not necessarily “halve” the diameter of the hole detected. That is why it is important that machines operating in line be calibrated to properly balance sensitivity and testing speed.

For example, a machine working in the laboratory processing four products per minute can detect holes with a diameter of 1 micron. A machine designed to operate on a production line tests 600 products per minute and needs to work at higher speeds, which affects its sensitivity. It will be able to identify hole diameters as small as 5 microns.

It is important to note that most international regulations do not require that tests be able to measure a specific size hole; only standards such as ASTM sometimes define the diameter of detectable holes, depending on the method and on the qualification parameters. This means that companies are free to choose the type of machine that best meets their needs and the performance level they want to achieve, in cooperation with a competent partner.

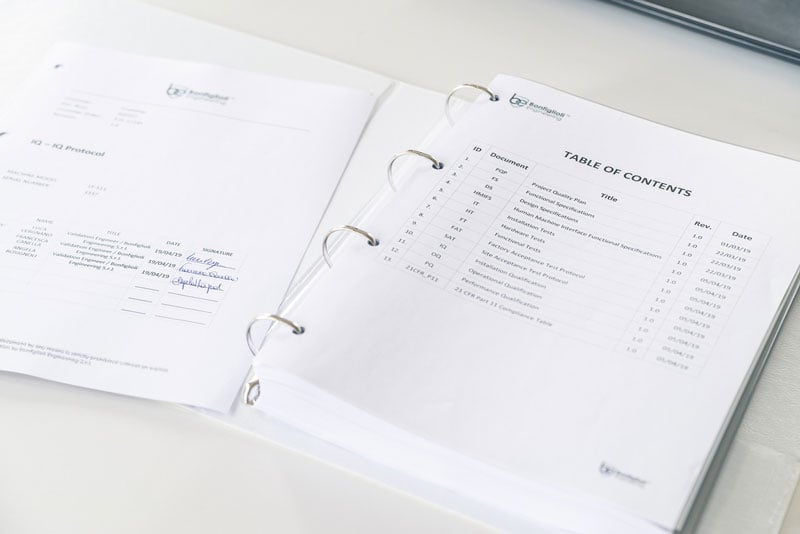

Thanks to our extensive experience in this sector, Bonfiglioli Engineering can offer companies personalized advice and design customized machines that adapt perfectly to their production line and guarantee optimal performance in every way, in compliance with international regulations and guidelines.

Would you like to learn more about what you should know before choosing a test method? Read our articles on Vacuum Decay versus High Voltage Leak Detection and Vacuum Decay method for rigid and flexible packaging inspection.

For further information or to begin designing a leak testing solution that meets your specific needs: contact us today.

Is it possible to accurately test filled containers that are running at a speed of 1000 containers per minute?