Effectively inspecting Blow-Fill-Seal (BFS) containers presents challenges because of the specific characteristics of this packaging type. International regulatory standards require that every container produced must be inspected. Because of these conditions, leak testing machines must be able to match the speed of the forming machine to achieve 100% inspection without creating bottlenecks or otherwise hampering the production line’s efficiency.

To meet these challenges and requirements, Bonfiglioli Engineering has developed a version of its PK-VS machine for high-speed Container Closure Integrity Testing (CCIT) of BFS products.

The PK-VS as explained by our Technical Sales Manager, Gianmarco Pincelli

Bonfiglioli Engineering Technical Sales Manager Gianmarco Pincelli notes that our automated system was developed specifically to test strips of single-dose BFS products with capacities that ranged from 0.1 ml to 20 ml.

BFS

FFS

IV Bags

To operate at high speed, the PK-VS equipment is connected to the automated packaging machine that blows, fills, and seals the products, and is loaded automatically through a conveyor belt.

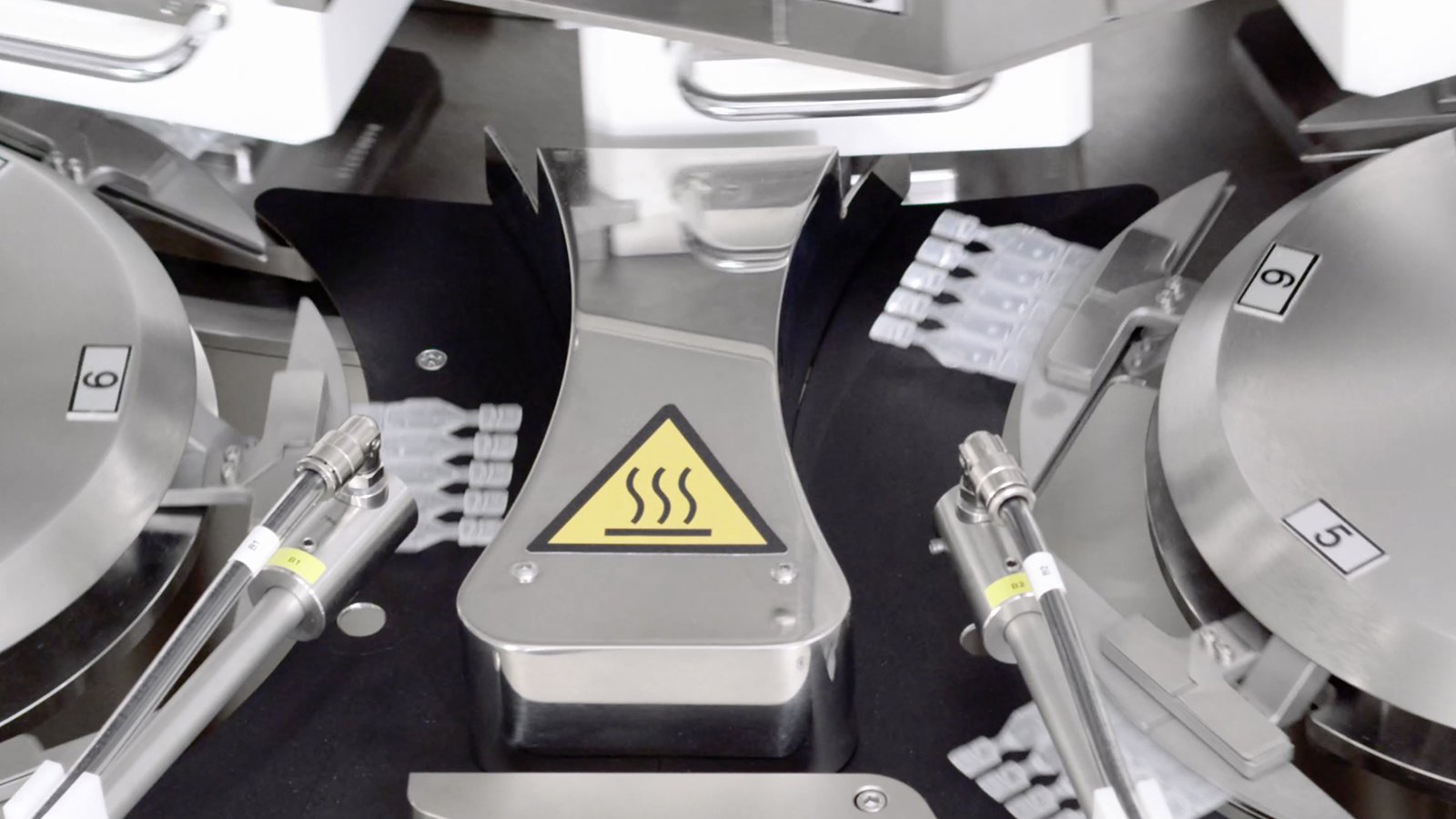

The products leave the thermoforming machine and the trimming machine in a vertical position. They are accumulated vertically, then rotated at 90° before being inserted into the PK-VS machine by mechanical grippers. The machine plates on which the grippers place products are closed by a mechanical cam with a spring return: the head closes on the product with a specific and controlled force to prevent accidental crushing if the products are poorly positioned.

Each strip loaded in the machine is placed in a separate test chamber, where it is undergoes vacuum testing. In order to guarantee a high test sensitivity without adversely affecting testing speed, a high vacuum level (10 mbar absolute) is used. The PK-VS can test more than 250 strips per minute, which is greater than the speed of the machine that blows, fills, and seals the products. “We were able to achieve this result by using a modern loading systems technology, which increased the speed from 220 to 250 strips per minute”.

The PK-VS is made entirely of stainless steel. Product handling and head movement are based on mechanical cams that are permanently lubricated, so they require no special maintenance.

The vacuum pumps used to generate an almost absolute vacuum are integrated into the machine base to save space, minimize the size of the pump, save energy, and significantly reduce noise levels inside the plant.

What benefits does the PK-VS provide?

High testing speed and high sensitivity are not the only advantages offered by the PK-VS. The system also:

-

Reduces false rejects through the automatic head exclusion system. When one of the test chambers becomes contaminated due to a leak, the machine automatically excludes that head, to prevent testing of new, intact, products from returning inaccurate or distorted results, thereby reducing the number of false rejects.

-

The Automatic Cleaning Pocket system automatically runs cleaning cycles to dry any contaminated heads.

-

Adjusts testing speed using Recovery Speed Adjustment. Since the machine that forms and fills the products operates at a constant speed, when one or more PK-VS heads are temporarily excluded, the others work at a higher speed to maintain the same productivity level and prevent strips from accumulating at input.

-

Testing pockets are easy to disassemble and replace as necessary, without the need to turn knobs or use tools.

-

Tests products of different capacities and with different filling levels, which can be difficult for other test methods like High Voltage Leak Detection.

-

Tests products made of different types of plastic, without affecting testing accuracy or speed.

-

Uses bypass mode, if necessary, to avoid testing certain product batches.

-

Uses remote machine operation supervision with the MES (Manufacturing Execution System), which can be connected to the company network to send reports, and request and receive assistance, in accordance with the principles of Industry 4.0.

-

Receives remote support from Bonfiglioli Engineering like for most testing systems, for machine diagnostics and operator training.

PK-VS: All the advantages guaranteed by Bonfiglioli Engineering’s experience

Bonfiglioli Engineering’s PK-VS effectively inspects BFS products, providing increasingly accurate and rapid results, minimizing false rejects, and guaranteeing high performance despite the challenges inherent to this type of product.

Contact our B.E.Experts to know more about the PK-VS and how we can help you with specific testing requirements.

Read about the challenges and solutions of BFS packaging and what makes it an ideal solution for aseptic manufacturing.