Critical for any company, product quality control becomes crucial in the pharmaceutical industry because of the potential threat to patient health if products are damaged or contaminated.

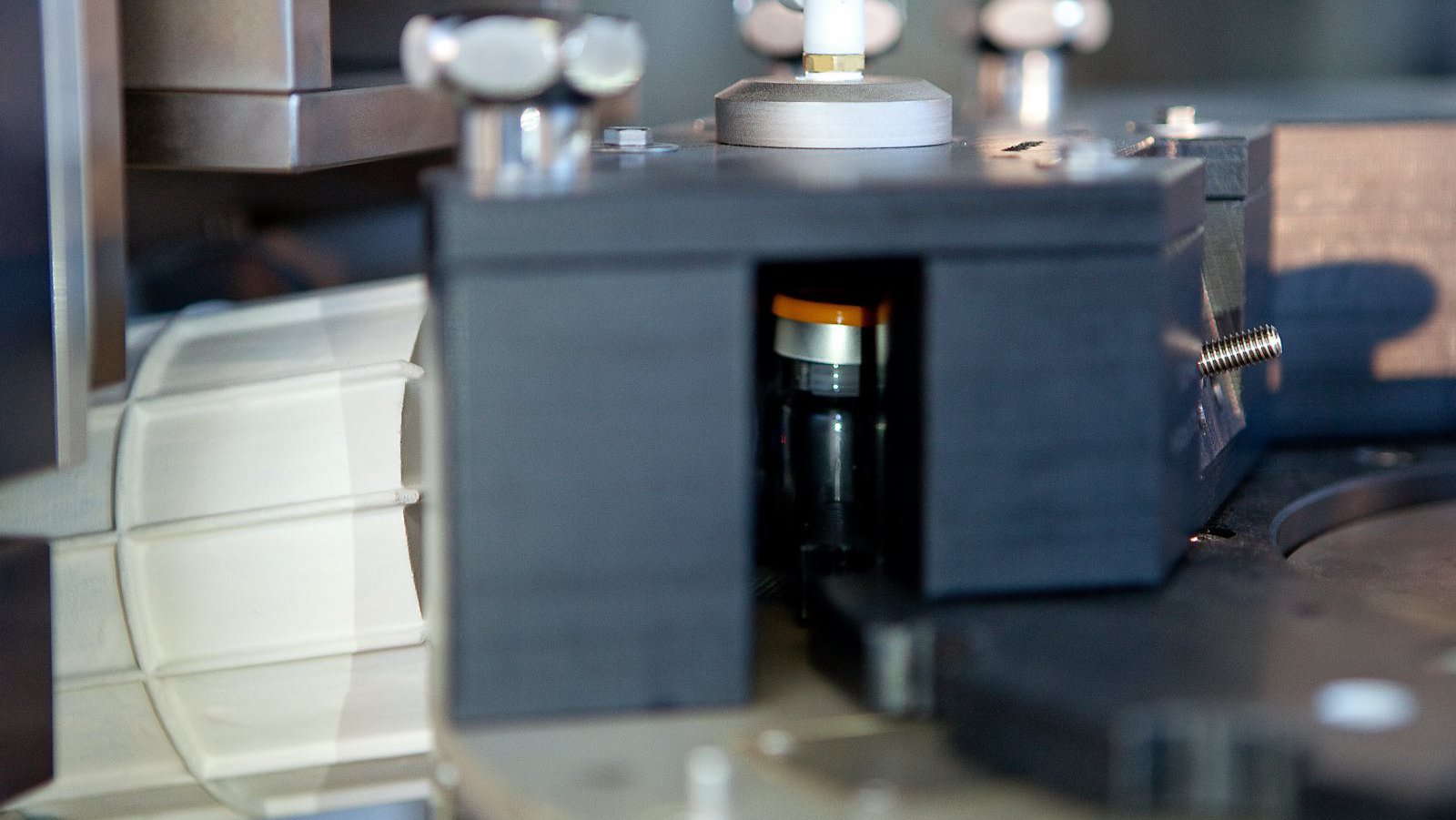

Automated test methods such as closure integrity testing and visual inspection offer rapid, reliable, and accurate results and help ensure that the products you sell are safe. A Headspace Gas Analysis (HGA) control system provides another method of ensuring container integrity and product safety. Here are five good reasons to include an HGA system in your product quality control process.

HGA is compliant with international regulations

The latest revision of USP <1207> on the container closure integrity test (CCIT) recommends deterministic rather than probabilistic analysis methods. The results offered by probabilistic integrity control methods, such as bubble testing or the methylene blue bath, are less accurate than deterministic analysis and cannot be applied to 100% of the production. Headspace Gas Analysis is a recognized deterministic method and can secure your company’s compliance with international regulations.

HGA verifies the quality of the production process

Headspace Gas Analysis not only detects possible container seal problems, but also provides information that can be used to improve the quality of the production process.

HGA can confirm that the product is correctly sealed and ensure that the appropriate protective atmosphere is present in the headspace. If, for example, the sample to be checked is a bottle containing a freeze-dried product in a nitrogen atmosphere, HGA should detect a very low oxygen concentration. If the product has more oxygen than expected, the capping machine is unable to close the bottle properly, or there may be a malfunction in the nitrogen cleaning system.

The result of an HGA not only identifies individual containers that do not meet the expected quality standards, but also provides information that when properly analyzed, can help your company identify potential problems in the production process, so you can correct any malfunctions. When received and acted upon early, this type of data can help you prevent loss of time and product, protecting your investment.

HGA determines the quality and quantity of the gases present in the headspace of the container to be tested

If a certain threshold value for the concentration of a certain gas or pressure level is exceeded, it offers a qualitative indication of the presence or absence of sealing issues for the container. However, HGA systems provide not only qualitative data, but also useful information about the quantity of such gases, which is very important for monitoring and improving processes and for collecting data for Industry 4.0. Quantitative analysis, for example, lets you determine whether the loss of a given gas increases over time, information that can allow your company take appropriate corrective measures to improve processes over time.

HGA measures total pressure inside the container

An HGA system not only measures the amount of gases present in headspace, but also the total pressure inside the container, providing very useful data in any container where a vacuum is used to protect the product.

If the internal pressure is not within the expected parameters, the required vacuum level may not have been reached when the product was sealed, or the container may have a leak (which can be confirmed by quarantining the product and monitoring for a loss of vacuum). Either of these two situations may indicate one of the following:

- Oxygen that can damage the active ingredient of sensitive drugs

- Water vapor that can compromise freeze-dried products

- Carbon dioxide that may indicate that the product has been contaminated by bacteria

The HGA system offer benefits beyond those of Headspace Gas Analysis alone

Designing an HGA system provides companies with an opportunity to obtain advice from the partner supplying and commissioning the automation system. A HGA solution is studied and designed based on the needs of the client company, and a large quantity of data is considered for its development, such as:

- Production speed

- Product type (powder, freeze-dried, liquid)

- Technique used to protect the product (nitrogen, helium, vacuum, etc.)

- Container Material type (tubular glass, molded glass, plastic, etc.)

- Container color (clear, amber, blue, opalescent)

- Container diameter

- Container shape (cylindrical or square)

- Fill level of individual products

- Required degree of test accuracy

- Structure, size, and organization of the production plant

By collecting, organizing, and evaluating these and many other types of data, the ideal automation system can be identified to meet the client’s needs. This means that the purchasing company can receive personalized consultancy leading to the installation of an automation system capable of effectively responding to its needs and improving its process.

Bonfiglioli Engineering provides varied solutions for leak detection and packaging integrity including Vacuum and Pressure Decay testing, Headspace Gas Analysis and Automatic Visual Inspection or even a mix of these, customized to fit client requirements.

We are not just a machine manufacturer. We are your trusted partner for packaging integrity testing and analysis through feasibility studies, technical expertise, validation packages, product handling and custom-built solutions.

Need to speak with an expert to understand the optimal leak detection method for your container type? Contact us now.

Learn more about our test methods