Metal packaging plays an important role in many industries, and the ability to test aluminium, tin or tinplate containers for leaks is essential in order to guarantee the quality—and, consequently, consumer safety—of many products.

Pressure or—more rarely—vacuum is generally used to test metal can packaging. In pressure decay testing, the product to be inspected is inserted into a hermetic test chamber in which a pressure differential is applied. In vacuum decay testing, the product is placed in a chamber in which a given vacuum level is applied. In both cases, the variation in the pressure or vacuum values after a given time interval, indicate a leak or leaks caused by holes in the container being tested.

The methods and speed of testing metal containers vary according to the type of container being inspected. In this sector, the products are divided into two macro-categories:

- Two-piece cans: are mainly used in the food industry for the packaging and preservation of canned goods. Two-piece cans are generally tested at relatively low pressures but at high speeds, with production lines running at velocities of up to 800-1,200 containers per minute (cpm).

- Three-piece cans: metal containers of this type are used in the food industry (e.g., for storing oil in tin cans), but in other sectors as well: aerosol cans containing oils, sprays, perfumes and similar products are usually inspected using medium pressure levels at low speeds, since the ASTM International standard requires that these products be tested with a high degree of sensitivity to detect even micro-holes with a very small diameter.

The type of product and the shape and size of the container to be inspected have a significant effect on both the test methods and the testing time: this means that each machine for testing these products must be developed in synergy with the customer, considering international regulations, the line’s speed of production and the desired degree of testing sensitivity.

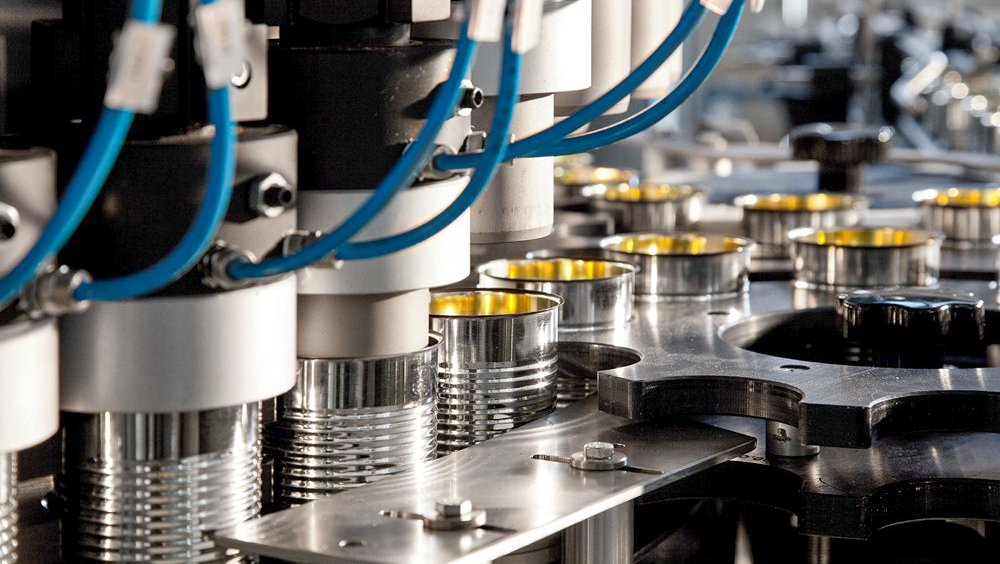

star loading system

star loading system

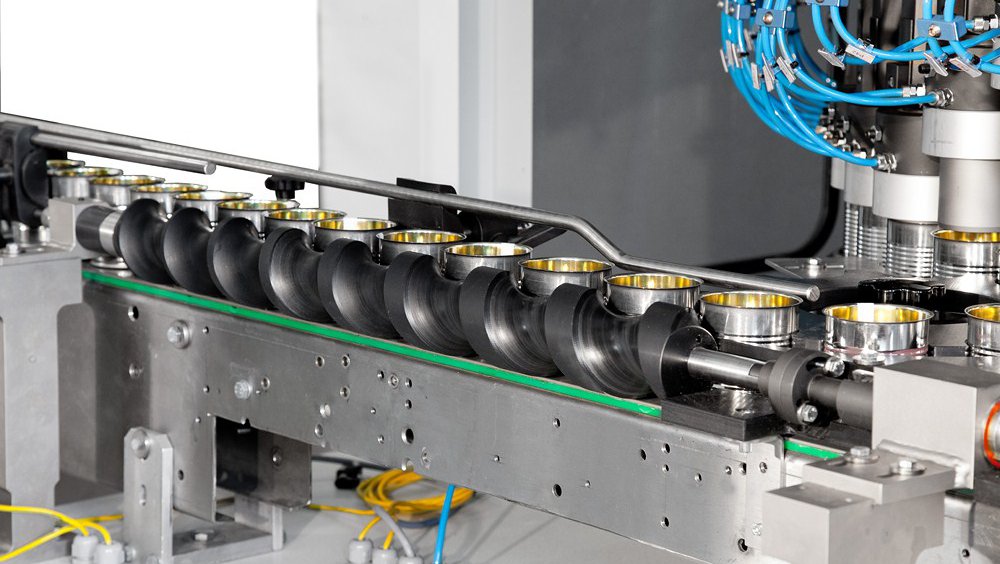

An example of the special features of the metal packaging test involves a specific type of two-piece can: the tuna can. These products are usually tested under pressure and on production lines running at very high speeds. Because the container is low in height and relatively wide, and a high number of products need to be tested per minute, special handling methods need to be developed to move the products and insert them correctly in the test chamber, without slowing down production. A star loading system is generally preferred in these cases (allowing automatic head exclusion, among other things), although the machine can also be fed via a screw-feeder for testing at lower speeds (fewer than 800 pieces per minute). So, when studying the most appropriate loading system, it is important to consider both the production speed and the shape of the container. By modifying the machine performing the test—the loading system can be changed quickly if the format of the product to be tested changes.

screw-feeder

screw-feeder

It is important to develop suitable handling methods for all the testing machines that operate on high-speed lines. This requires design and size customization, considering both the customer's needs and the space and time necessary for the entire system to operate efficiently. Proper sizing of the machine and the conveyor belt, together with careful development of line engineering in terms of both mechanics and software is a fundamental step in the designing and installing of the machine that will test metal containers.

With over 45 years of experience in closed container package inspection, Bonfiglioli Engineering can help determine what the best method and solution are for your metal packaging inspection needs. To learn more, contact us now.