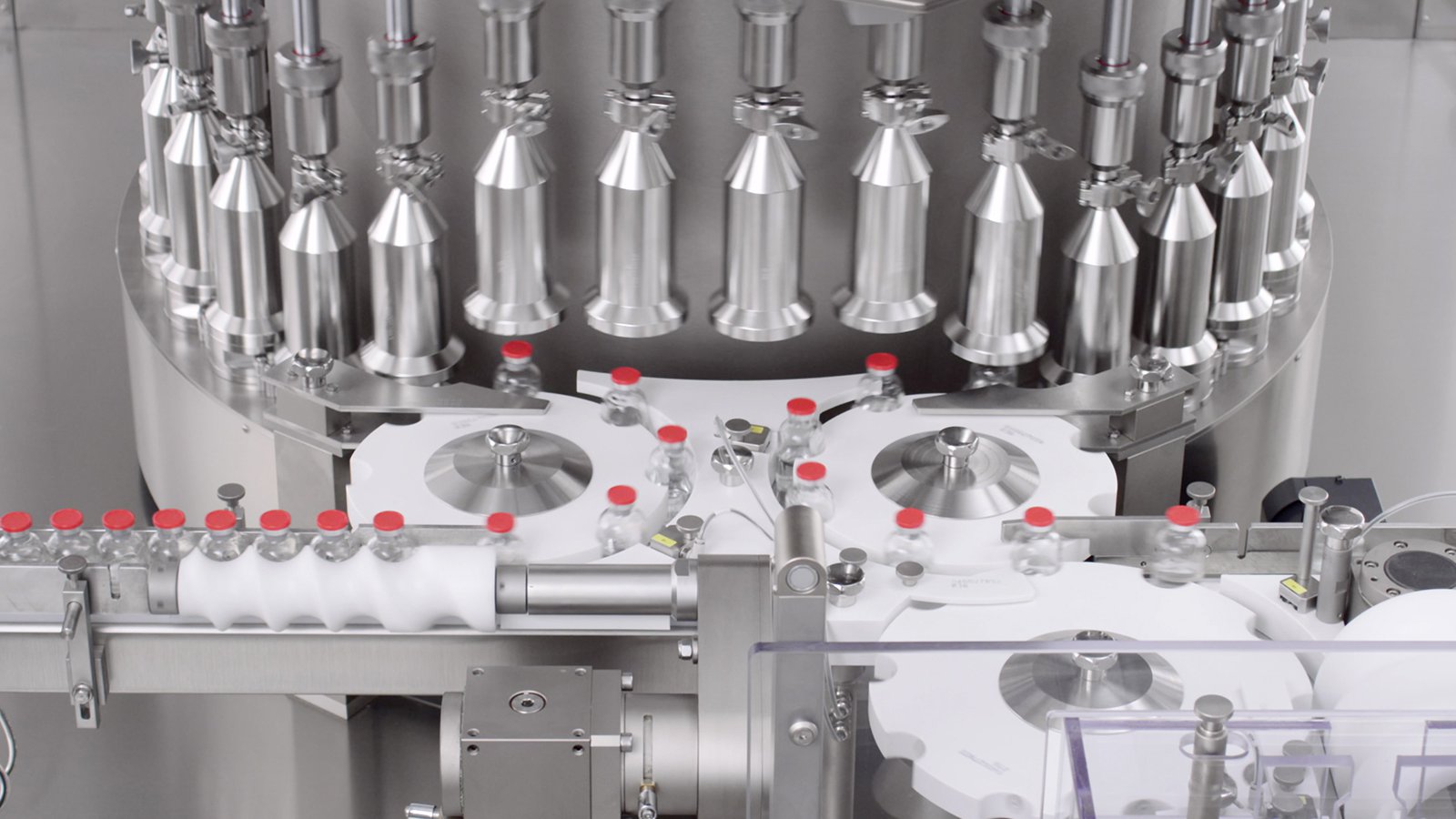

Every integrity testing machine for pharmaceutical products is the result of a long phase of study and design, necessary to provide our customers with equipment that delivers optimal reliability, efficiency, and durability and can be seamlessly integrated into a production line.

Bonfiglioli Engineering understands that, while the manufacture of pharmaceutical products have requirements and realities in common, each customer and operating environment is unique. We study each project in depth to understand each customer and product’s needs and choose the materials most suited to delivering the required results.

The design phase involves more than just technology and mechanical attributes: great attention also needs to be paid to the choice of materials to be used. From the base structure of the machine to surface treatments and specialty components, choosing the right materials is a fundamental step in offering testing solutions that fully meet our customers’ needs, operate optimally, and maintain their efficiency over time.

Designing a pharmaceutical testing machine:

1. Choosing the right materials

The first component of material choice involves identifying the main function of the machine and the operating conditions in which it will be placed. Stainless steel is more able to withstand aggressive washing, while other materials may be lighter weight and easier to move from one line to another. Understanding the environment and requirements of the equipment helps our engineers determine the material that will deliver reliable, efficient test results for a long time to come.

Once these basic conditions are considered, we turn our attention to our customer’s specific requirements and any relevant regulatory demands. For example, international regulations require that some machines be manufactured entirely of certified materials, which clearly guides material choices during the design phase.

2. Surface treatments

Once the material has been chosen, the design process proceeds, focusing on increasingly detailed aspects, such as the type of surface treatment to be applied to individual machine components in order to protect the products being tested and maintain optimal line speed and equipment durability.

The parts of the machine that come into direct contact with the product must be polished to prevent friction that could damage the test sample. We also must ensure the product slides through the machine smoothly. Powders such as PTFE can be applied to metal parts to reduce friction on plastic products.

Component surface treatments are also needed to protect certain machine materials and ensure they stand up to aggressive washing and sanitizing. We work closely with our suppliers to choose and source the right combination, from nickel plating for aluminum components, to cataphoresis for iron or steel engineering solutions, to hardening treatments on critical elements like machine cams.

3. Specialty components and applicationsons

Lastly, we take great care when selecting materials for machine parts that perform specific functions, such as small components bearing high loads or large components that need to be capable of certain dynamic behaviors. In these cases, we often use special alloys, like nickel-chromium-molybdenum steel for shafts that are put under extreme strain, or specially-treated Ergal (an aluminum alloy), for its ability to resist corrosive agents.

Building the ultimate testing solution for pharmaceutical products requires extensive knowledge of production operating environments, international regulations, and material characteristics. For Bonfiglioli Engineering, choosing the best material is not based solely on a structural calculation: every project is studied in-depth, understanding the materials best suited to each task the machine will have to perform and taking our customers’ specific needs and environment into account.

Every Bonfiglioli Engineering machine is a dedicated solution built with our customers in mind, the fruit of our long-term expertise, experience and passion.